Development and Application of Carbon Fiber Reinforced Composites in National Defense and Military Fields

With the continuous advancement of technology, especially breakthroughs in materials science, carbon fiber reinforced composites (CFRP) have become a vital component of modern military technology. Thanks to their unique combination of high strength, stiffness, low density, and corrosion resistance, CFRPs have found extensive applications in military aviation, ground combat equipment, naval ships, and protective gear. This article explores the development history, current applications, and future trends of CFRPs in national defense and military fields.

I. Key Characteristics of Carbon Fiber Reinforced Composites

Carbon fiber reinforced composites are a type of high-performance material made from carbon fibers and a resin matrix. The key advantages of CFRPs include:

- High Strength and Stiffness: Carbon fibers offer exceptional tensile strength and stiffness, several times greater than metals, while also providing excellent fatigue resistance.

- Low Density: Compared to traditional metals, CFRPs are much lighter, significantly reducing the weight of military equipment.

- Corrosion and High-Temperature Resistance: CFRPs are highly resistant to corrosion from moisture, acids, and bases, and can withstand high temperatures, making them ideal for harsh combat environments.

- Design Flexibility: CFRPs can be tailored to meet specific performance requirements by varying fiber orientation and selecting appropriate resin systems.

These advantages have made CFRPs increasingly replace traditional metal materials in military applications, becoming an essential part of modern military systems.

II. Applications of Carbon Fiber Reinforced Composites in Military Fields

- Military Aviation

Aviation technology is one of the areas where carbon fiber reinforced composites are most widely used. Whether in fighter jets, transport aircraft, or unmanned aerial vehicles (UAVs), CFRPs play a crucial role in enhancing performance, reducing weight, and improving combat effectiveness.

Fighter Jets: Modern fighter aircraft have demanding material requirements. To enhance maneuverability, reduce aircraft weight, and improve stealth capabilities, many countries have begun using large amounts of CFRPs in their fighter jets. For instance, the U.S. F-22 Raptor and F-35 Lightning II both extensively use CFRPs in the construction of their airframes and wings. These materials not only improve aircraft performance but also contribute to a lower radar cross-section (RCS), enhancing stealth capabilities.

|

|

Unmanned Aerial Vehicles (UAVs): UAVs require lightweight construction with excellent flight performance, making CFRPs an ideal choice. For example, the U.S. MQ-9 Reaper UAV incorporates extensive use of CFRPs, reducing the weight of the drone while maintaining sufficient structural strength to carry heavier payloads and execute complex missions.

|

|

- Ground Combat Equipment

The use of CFRPs in ground combat equipment is also widespread, particularly in heavy military vehicles, where they offer significant advantages.

Tanks and Armored Vehicles: Modern tanks and armored vehicles require enhanced protection and mobility. By using CFRPs, military engineers can reduce the weight of these vehicles while improving their strength and armor protection. For example, some modern armored vehicles and tanks have started using CFRPs in their outer shells to reduce weight and improve fuel efficiency, while still maintaining high ballistic protection.

|

|

Portable Weapons: Portable weapons like rocket-propelled grenades and anti-tank missiles have also benefited from CFRP usage. The lightweight yet strong characteristics of CFRPs enable these weapons to remain effective while being easier to carry and deploy in the field.

|

|

- Naval Ships and Submarines

Naval assets, especially ships and submarines, face unique challenges due to the harsh marine environment. CFRPs are increasingly used in these applications because of their excellent resistance to corrosion and pressure, alongside their ability to reduce weight.

Warships: Some new warships have started incorporating CFRPs in their hulls to improve their strength and reduce weight, resulting in enhanced speed and maneuverability. CFRPs are also used in parts of the ship’s deck and weapons systems, leading to better performance in challenging environments.

|

|

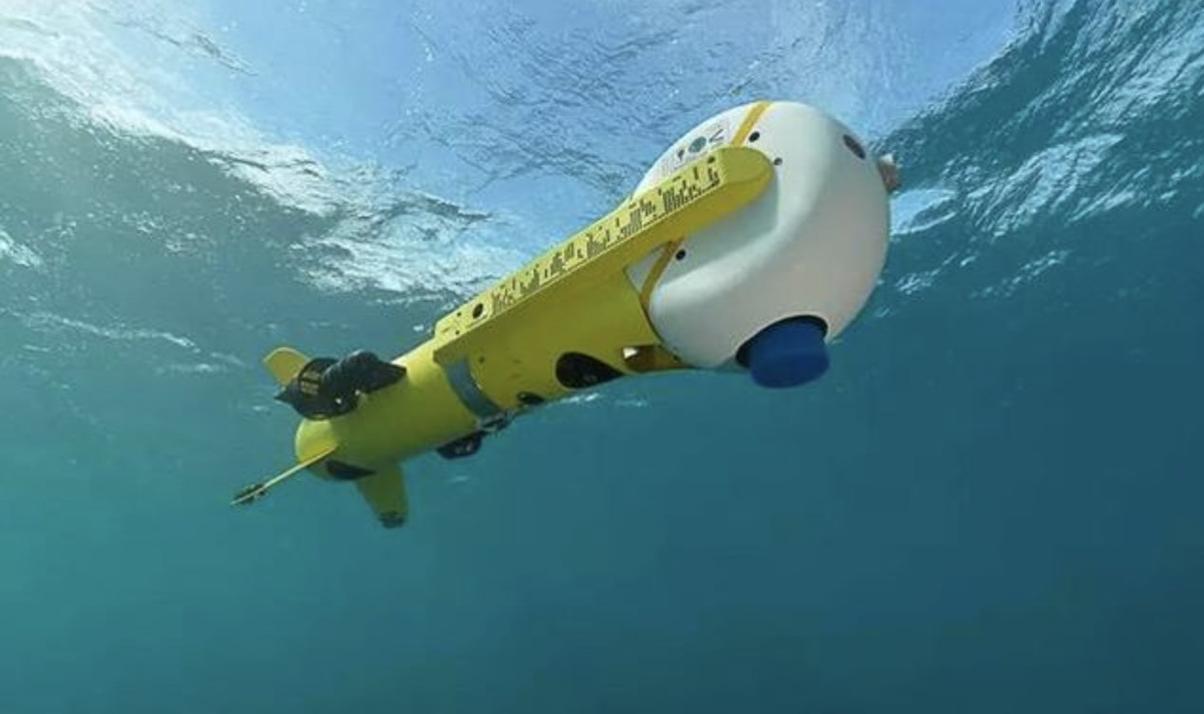

Submarines: Submarines require materials that can withstand extreme pressures while resisting corrosion from seawater. CFRPs’ durability and resistance to environmental factors make them a good fit for submarine design. By optimizing the use of CFRPs, designers can reduce the weight of submarines, enhancing their depth capabilities and maneuverability.

|

|

- Personal Protective Equipment

As battlefield conditions evolve, the need for lighter, more efficient personal protective gear becomes ever more critical. CFRPs have significantly improved the performance and comfort of military uniforms and protective gear.

Body Armor: Traditional body armor was primarily made of metal and ceramic materials, which were often heavy and uncomfortable over long periods. Modern body armor increasingly incorporates CFRPs, which offer the dual benefits of high ballistic protection and reduced weight, allowing soldiers to remain more agile during combat.

|

|

Helmets and Protective Gear: CFRPs are also used in military helmets and knee/elbow guards, providing enhanced protection while reducing the overall weight of the gear. This not only improves soldier mobility but also ensures that the equipment can withstand high-impact forces in battle.

|

|

III. Challenges of Carbon Fiber Reinforced Composites in Military Applications

Despite their many advantages, there are still several challenges to overcome in the use of CFRPs in military applications.

-

Cost Issues: CFRPs are expensive to produce, and although costs have gradually decreased with technological advances, the high production cost remains a challenge for large-scale military production.

-

Manufacturing Complexity: The production of CFRPs involves complex processes, particularly when it comes to mass production. Ensuring consistent quality and performance across large quantities of components is a challenge for military manufacturers.

-

Repair and Recycling Issues: CFRPs are difficult to repair once damaged, and recycling these materials is complex. This poses a challenge for maintaining and servicing military equipment in the field, especially in combat situations.

IV. Future Trends

With ongoing advancements in carbon fiber technology, the future holds even greater potential for CFRPs in the military domain. Several key trends can be expected:

-

Smart Materials: The development of self-healing carbon fiber composites could revolutionize military applications. These materials would be capable of automatically repairing damage, reducing maintenance costs and enhancing operational readiness.

-

3D Printing: The integration of CFRPs with 3D printing technology could further reduce manufacturing costs and increase production efficiency, allowing for faster prototyping and on-demand production of military equipment.

-

Advanced Hybrid Composites: The future of CFRP applications in the military may involve hybrid composites that combine carbon fibers with other materials like graphene or carbon nanotubes. These advanced composites could offer even better performance in terms of strength, weight, and resistance to extreme conditions.

Conclusion

Carbon fiber reinforced composites have become an essential material in modern military systems, playing a vital role in enhancing the performance, mobility, and protection of military assets. From aviation to ground vehicles, naval ships, and personal protective equipment, the application of CFRPs has revolutionized military technology. While there are still challenges to address, such as cost, manufacturing complexity, and repairability, the future of CFRPs in military applications looks bright, with significant potential for further innovation and widespread use. As technology continues to evolve, CFRPs will undoubtedly continue to play a critical role in shaping the future of defense and military capabilities.