The Application and Development of Carbon Fiber Reinforced Polymer (CFRP) in Rail Transportation

With the rapid development of rail transportation technologies, the demand for advanced materials has increased significantly. To meet the challenges of high speed, safety, energy efficiency, and environmental protection, carbon fiber reinforced polymer (CFRP) has emerged as a key material due to its outstanding properties. From high-speed train carriages and subway interiors to various components in rail infrastructure, CFRP is reshaping the structure and functionality of traditional rail systems with its unique advantages.

I. Unique Advantages of CFRP

CFRP is a composite material made by combining carbon fiber as a reinforcement and resin as the matrix. It offers several key advantages:

-

Lightweight and Energy Efficiency

CFRP has a density about one-quarter that of steel and one-half that of aluminum, making it extremely lightweight. This lightweight nature significantly reduces the overall weight of rail vehicles, which in turn reduces energy consumption and improves efficiency. For high-speed trains, a lighter carriage helps lower air resistance, enhancing both acceleration and deceleration efficiency. -

High Strength and Safety

Carbon fibers possess tensile strength several times greater than steel, allowing them to withstand higher stress and impacts. CFRP's high strength makes it suitable for critical parts of rail vehicles, improving collision resistance and ensuring better passenger safety. -

Corrosion and Weather Resistance

CFRP is highly resistant to chemicals, moisture, and environmental conditions, making it ideal for long-term use in harsh environments. It can effectively resist corrosion in humid or coastal areas, extending the service life of rail vehicles and infrastructure.

II. Practical Applications of CFRP in Rail Transportation

The exceptional performance of CFRP has led to its widespread use in rail transportation. Below are some practical cases and application scenarios.

1. High-Speed Train Carriages

CFRP is increasingly used in the carriages of high-speed trains. For example, China's Fuxing high-speed train and Japan’s Shinkansen both incorporate CFRP in various parts of the train body. The Fuxing train has used CFRP in parts of the external body and structural components, reducing the weight of the carriage by approximately 15%. This weight reduction not only improves energy efficiency but also enhances the train's speed and stability.

In addition, CFRP plays an important role in the impact absorption zones and the front design of the train. Its superior energy-absorbing capability allows it to better distribute impact forces during high-speed operation or in the event of an emergency, thus enhancing passenger safety.

2. Subway Vehicle Interiors and Structural Components

In urban rail transportation, CFRP is also widely used for subway vehicle interiors and critical structural components. For example, London Underground has started using CFRP in the interiors and some seats of new trains. This not only reduces the weight of the carriages, improving energy efficiency, but also enhances the aesthetics and comfort of the train.

Similarly, Tokyo Metro has adopted CFRP extensively in subway carriages. These materials offer strong resistance to impacts and wear, making them more durable and less prone to damage from frequent use. Furthermore, the flexibility in design allows for modern, attractive aesthetics in the carriages.

|

|

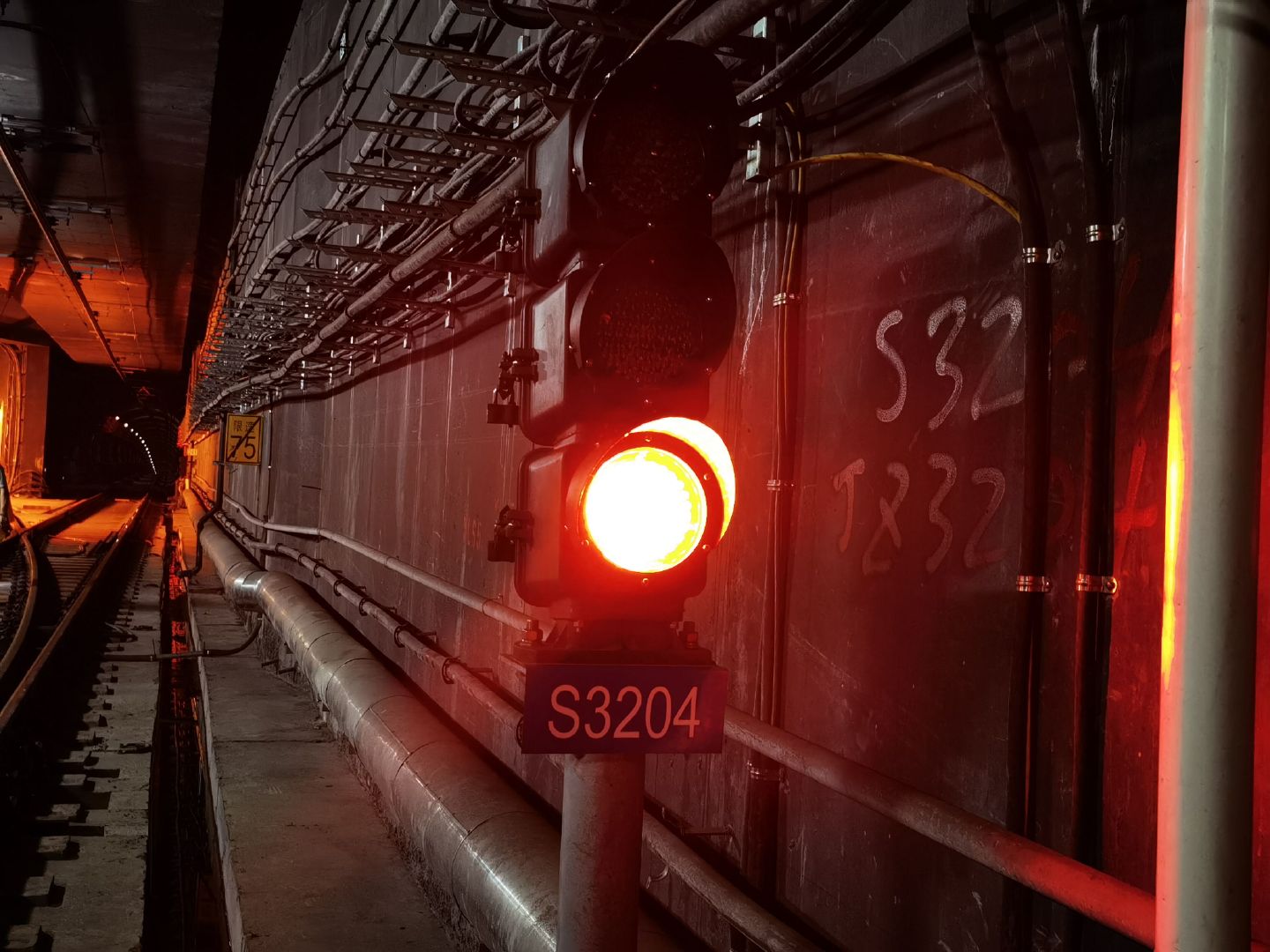

3. Rail Infrastructure: Signal Equipment and Station Facilities

CFRP is also being used in rail infrastructure, such as in signal equipment and various components of station facilities. For example, in Singapore’s MRT, CFRP is used in structural components like support rods, track maintenance platforms, and even station columns. Compared to traditional materials, CFRP is lighter and more resistant to corrosion, making it ideal for rail facilities that are exposed to moist and corrosive environments.

Additionally, Berlin’s S-Bahn has employed CFRP in signal equipment support structures. These components are often exposed to outdoor conditions, and CFRP's durability against weathering and UV radiation makes it a preferred choice.

|

|

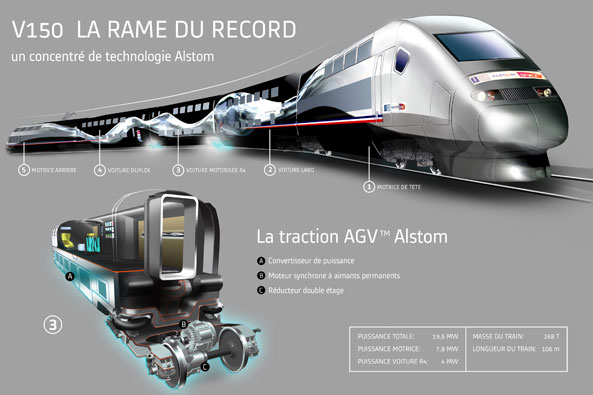

4. High-Speed Train Components: Suspension Systems and Brake Systems

CFRP is also used in key components of high-speed trains, such as suspension and braking systems. For instance, the TGV trains in France have incorporated CFRP in the suspension system. The primary function of the suspension is to support the train and absorb vibrations, and CFRP’s lightweight and high-strength characteristics improve its efficiency and durability, reducing maintenance needs and operating costs.

Additionally, CFRP is employed in train braking systems. Its high rigidity and resistance to high temperatures allow it to withstand the heat generated during braking, improving the safety and longevity of the braking components.

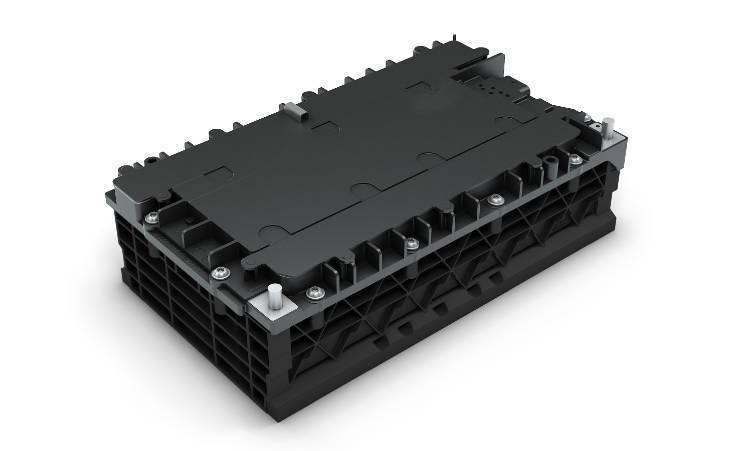

5. Rail Inspection and Electrical Equipment Housings

As rail transportation facilities become more intelligent, CFRP is being applied to rail inspection equipment, power supply facilities, and other systems. For example, in Zurich, Switzerland, CFRP is used for the housings of rail inspection devices. These components are typically exposed to harsh conditions, and CFRP's lightweight and corrosion-resistant properties make it an excellent choice for reducing equipment failure rates and maintenance costs.

|

|

III. Future Trends and Challenges

While CFRP offers significant advantages in rail transportation, several challenges remain. One of the main challenges is its relatively high production cost, which limits its widespread use. However, as manufacturing processes improve and economies of scale are realized, the cost of CFRP is expected to decrease, which will further expand its application.

Moreover, as environmental concerns increase, the recycling and reusability of CFRP also need to be addressed. Currently, CFRP recycling technologies are still under development, and improving the sustainability and recyclability of this material will be a key focus in the future.

IV. Conclusion

CFRP, with its unique advantages, is playing an increasingly important role in the rail transportation industry. Whether in high-speed train carriages, subway interiors, or various rail infrastructure components, CFRP is transforming modern rail systems with its lightweight, high-strength, and corrosion-resistant properties. As technology advances and production costs decrease, the applications of CFRP in rail transportation are expected to continue to grow, shaping the future of the industry and improving both efficiency and safety for passengers.