The Role and Development Prospects of Carbon Fiber Composites in the Medical and Medical Devices Field

Carbon fiber composites, as a high-performance material, have been widely used in fields such as aerospace and the automotive industry. In the medical field, carbon fiber composites are gradually becoming an important material due to their unique properties. They have significant applications in medical devices, diagnostic tools, surgical instruments, and more, showing a promising future. This article will provide a detailed overview of the role, advantages, and future development prospects of carbon fiber composites in the medical and medical devices sectors.

1. Basic Characteristics of Carbon Fiber Composites

Carbon fiber composites consist of carbon fibers embedded in a resin matrix. They are known for their high strength, low weight, corrosion resistance, high temperature resistance, and excellent mechanical properties. The strength of carbon fibers is five times that of steel, yet their density is only one-fourth that of steel, achieving an ideal balance between weight and strength. In addition, carbon fibers have outstanding electromagnetic shielding properties and good biocompatibility, making them an ideal choice for various high-precision medical devices and applications.

2. Applications of Carbon Fiber Composites in Medical Devices

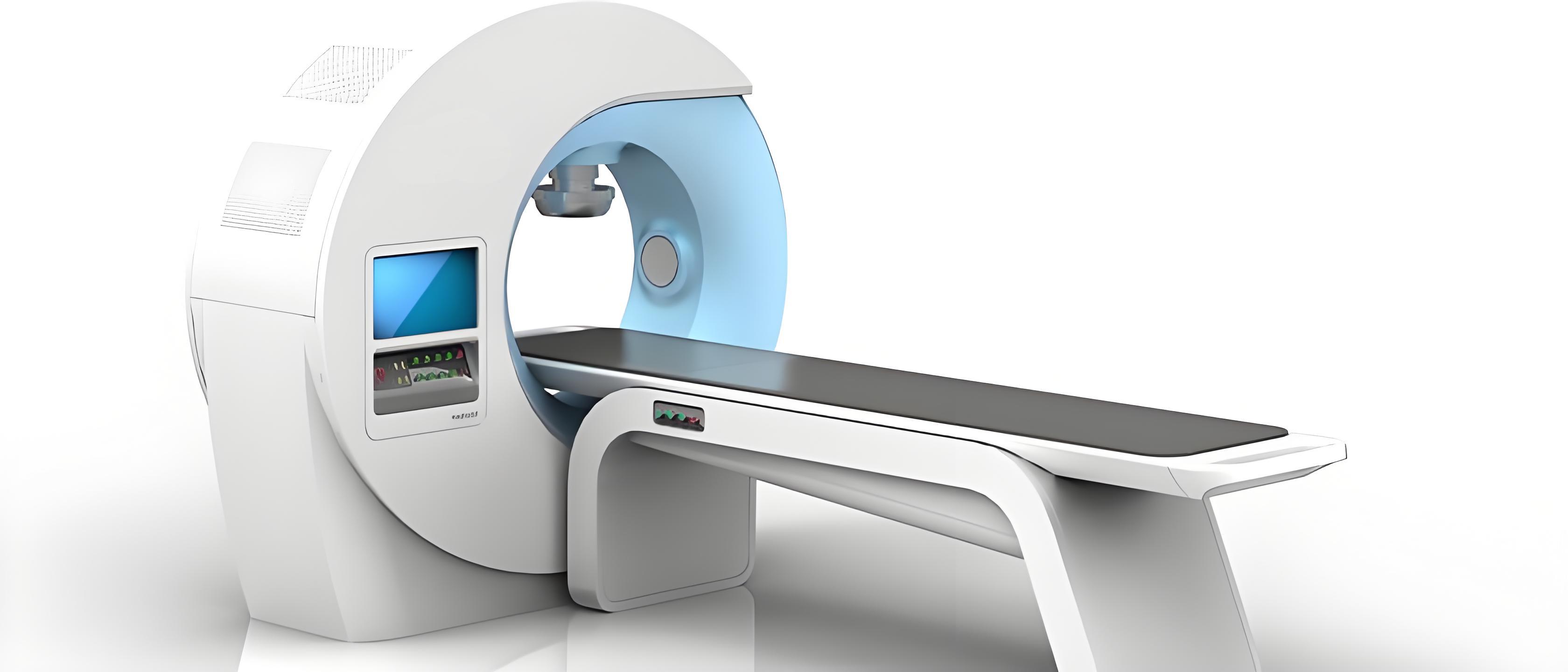

1. Medical Imaging Equipment

One of the most important areas of carbon fiber composites' application in medicine is in medical imaging equipment. Traditional medical imaging devices, such as X-ray machines, CT scanners, and MRI machines, require precision mechanical structures and high-strength materials. Carbon fiber composites, with their high strength and low density, make them an ideal material for the frames and supports of such equipment.

For instance, in CT scanners, carbon fiber composites are used to create structural supports or frames, which reduce the weight of the equipment, increase flexibility, and enhance operational precision. Additionally, the low X-ray absorption of carbon fiber helps improve the quality and accuracy of the images, enabling better detail capture of internal body structures.

2. Surgical Instruments

Carbon fiber composites have widespread use in surgical instruments. In surgery, instruments must possess high strength and precision while being lightweight and corrosion-resistant. Carbon fiber composites meet these demands. For example, surgical tool handles, forceps, and clamps need to remain sharp for extended periods and withstand considerable mechanical stress. Due to their excellent strength and rigidity, carbon fiber materials ensure the functional integrity of surgical instruments.

Moreover, carbon fibers have a low coefficient of thermal expansion, which helps maintain the accuracy and stability of surgical instruments in high-temperature environments, making them particularly beneficial for minimally invasive surgeries.

3. Implantable Medical Devices

Carbon fiber composites are also widely used in implantable medical devices. Joint replacements, spinal fixation devices, bone fracture plates, and other implants require high biocompatibility and mechanical properties. Carbon fiber's high strength and excellent biocompatibility make it an ideal choice for such devices. Studies have shown that carbon fiber composites integrate well with bone tissue and reduce the likelihood of rejection reactions, making them ideal for implantation.

Additionally, the low thermal conductivity of carbon fiber helps minimize the impact of external temperature changes on implant materials, improving patient comfort.

|

|

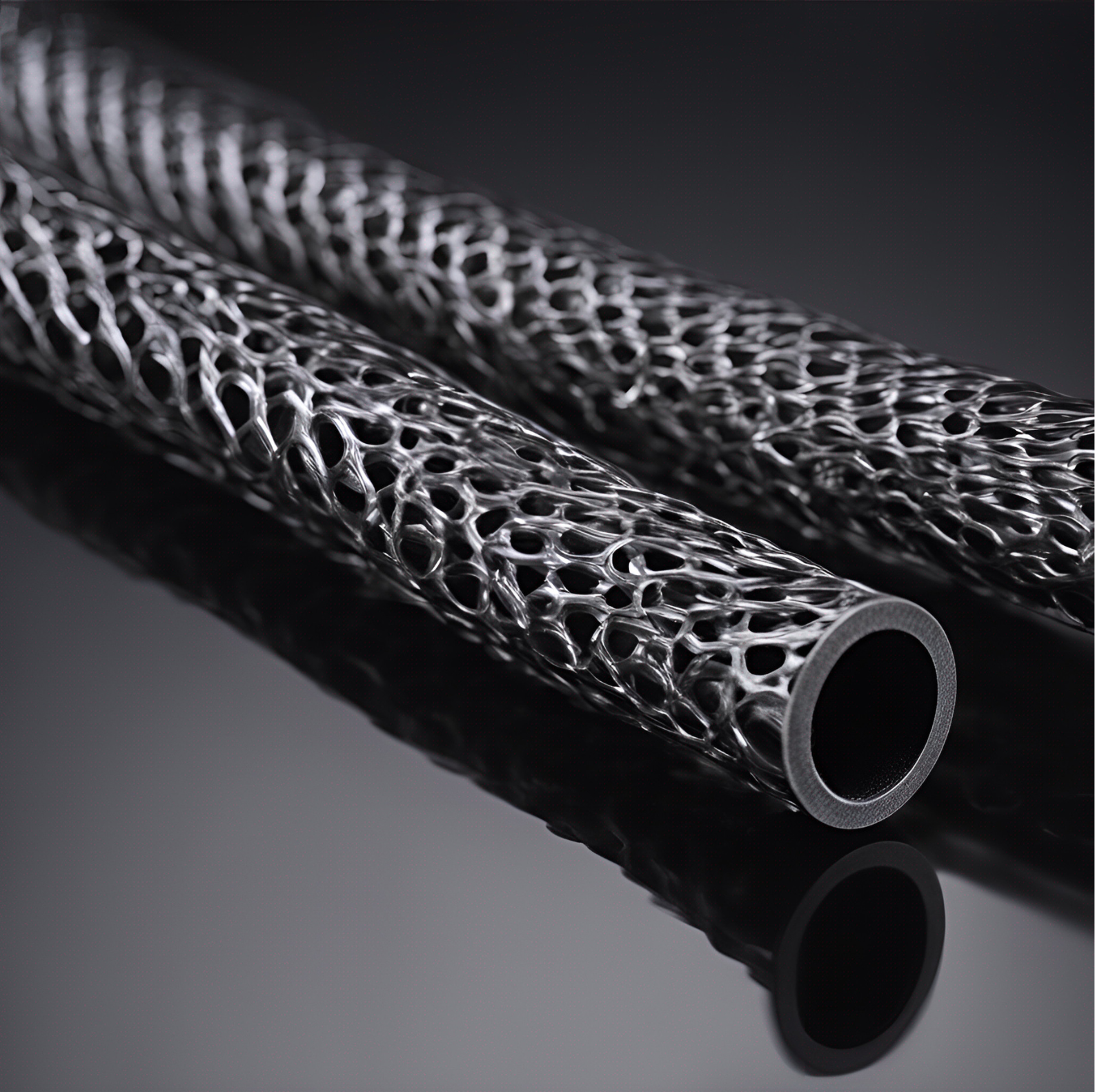

4. Medical Stents and Support Structures

Medical stents, such as bronchial stents and vascular stents, play a crucial role in many medical treatments. Traditional stent materials, such as stainless steel, offer good mechanical properties, but they may cause inflammation or adverse reactions with the body. Carbon fiber composites have addressed this issue. Due to their excellent mechanical properties and biocompatibility, carbon fiber materials are increasingly replacing traditional metals in medical stents.

|

|

5. Prosthetics and Orthopedic Devices

For people who have lost limbs due to injury or congenital conditions, prosthetics and orthopedic devices are critical to restoring their quality of life. Carbon fiber composites, due to their superior strength-to-weight ratio, are ideal materials for making prosthetics and orthopedic devices. Carbon fiber prosthetics are lighter than traditional metal prosthetics, offering more comfort to the wearer. Additionally, carbon fiber's strength ensures that prosthetics can withstand long-term use without deformation, ensuring stability and durability.

|

|

3. Advantages of Carbon Fiber Composites in the Medical Field

1. Lightweight

The lightweight nature of carbon fiber composites is one of their greatest advantages in the medical field. Many medical devices, such as surgical instruments, medical imaging equipment, and implantable devices, require low weight to facilitate easier handling and reduce patient discomfort. The low density of carbon fiber significantly reduces the weight of these devices, enhancing both usability and patient comfort.

2. High Strength and Durability

Carbon fiber composites are known for their remarkable strength and durability, enabling them to withstand substantial mechanical stress. In the medical device field, especially for surgical instruments and implantable devices, the strength and longevity of the materials are crucial. Carbon fiber composites can provide excellent mechanical properties while maintaining their lightweight nature, meeting the high demands for strength in medical applications.

3. Excellent Biocompatibility

Another key advantage of carbon fiber composites in the medical field is their excellent biocompatibility. Carbon fiber materials do not provoke significant immune reactions when implanted into the body and integrate well with human tissue. This makes them ideal for use in implantable medical devices, where reducing rejection reactions is crucial for patient recovery.

4. Corrosion and Wear Resistance

Carbon fiber composites are highly resistant to corrosion and wear, which is particularly important for medical devices used in moist or harsh environments. This property ensures the long-term reliability and durability of medical instruments, making carbon fiber materials an ideal choice for devices that are in constant contact with the human body.

4. Future Development Prospects of Carbon Fiber Composites in the Medical Field

As carbon fiber composite manufacturing technologies continue to improve and costs decrease, the use of these materials in the medical field is expected to expand significantly. In particular, their applications in medical imaging, surgical instruments, implantable devices, and prosthetics hold great promise. Future research will likely focus on enhancing the biocompatibility, processing techniques, and durability of carbon fiber composites, further promoting their use in the medical sector.

1. Development of Smart Medical Devices

The future development of smart medical devices will further accelerate the use of carbon fiber composites. For example, intelligent prosthetics and surgical instruments integrated with sensors will require materials that offer high precision and advanced functionality. Carbon fiber composites, with their ability to provide strength and stability while enabling miniaturization, will support the development of these next-generation devices.

2. Green Healthcare and Sustainability

With the growing emphasis on green healthcare and sustainable development, carbon fiber composites—due to their lightweight, durability, and recyclability—are becoming a key direction for eco-friendly medical devices. In the future, the recycling technologies for carbon fiber materials will continue to mature, which will further drive the adoption of these materials in the medical field.

|

|

5. Conclusion

As a high-performance advanced material, carbon fiber composites hold vast potential in the medical field. From medical imaging devices to surgical instruments, implantable devices, and prosthetics, the high strength, lightweight nature, excellent biocompatibility, and corrosion resistance of carbon fiber composites make them an ideal choice in a variety of medical applications. With advancements in technology, carbon fiber composites will play an increasingly significant role in the medical field, offering patients more accurate, safer, and more comfortable medical services.