In-Depth Analysis of Carbon Fiber Composites in the Aerospace Sector

Carbon fiber composites, with their unique characteristics of lightweight and high strength, have become a core material in the aerospace sector. Engineers are continually exploring the potential of these materials to meet the increasing demands for performance, fuel efficiency, and durability in modern aircraft. This article delves into the practical applications of carbon fiber composites in various aerospace fields, highlighting their significant impact on improving flight performance and operational efficiency.

1. Applications in Aircraft Fuselage and Wing Structures

1. Large Passenger Aircraft: Boeing 787 and Airbus A350

- The Boeing 787 Dreamliner stands as a testament to modern aviation technology, with approximately 50% of its airframe made from carbon fiber composites, including critical components like wings, tail sections, and fuselage skin. This significantly reduces the aircraft's weight, resulting in roughly 20% fuel savings compared to traditional aluminum aircraft.

- The Airbus A350 XWB uses carbon fiber composites for its wings, fuselage, and vertical stabilizer, achieving longer ranges and lower carbon emissions. This design not only improves fuel efficiency but also extends the aircraft's range, making it ideal for long-haul flights.

2. Narrow-Body and Regional Jets

- Many narrow-body aircraft, such as the Boeing 737 MAX series and Airbus A320neo, are increasingly adopting carbon fiber composites to enhance fuel efficiency and reduce maintenance costs. In particular, reinforced wing designs help boost cruising speed and range.

2. Structural Support in Satellites and Space Probes

1. Solar Panels and Antenna Mounts

- In satellite manufacturing, carbon fiber composites are widely used for solar panel substrates and antenna mounts. The material’s low thermal expansion coefficient and radiation resistance enable satellites to operate with high precision under extreme temperature variations and radiation conditions.

- For instance, NASA’s Juno probe, which explores Jupiter, employs carbon fiber composites in its solar panel supports to ensure stability in the frigid conditions of Jupiter's orbit.

2. Deep Space Probes: Mars Exploration Missions

- The Perseverance rover, part of recent Mars exploration missions, utilizes carbon fiber composites, especially in its robotic arm and instrument mounts. Its lightweight design helps reduce launch weight, lower costs, and enhance mobility and stability on the Martian surface.

3. Lightweight Design in Aircraft Engines

1. Turbofan Engine Fan Blades

- Modern efficient engines, like GE’s GEnx and CFM’s LEAP series, extensively use carbon fiber composites in fan blades and casings. Carbon fiber fan blades not only reduce engine weight but also enhance thrust-to-weight ratios.

- For example, the GEnx engine's fan blades are approximately 20% lighter than traditional titanium blades, which significantly increases fuel efficiency, especially on long-haul routes.

2. Electric Aircraft Propulsion Systems

- As electric aircraft technology advances, carbon fiber composites are used in electric engine casings and internal components to reduce system weight and improve battery efficiency. These innovative designs are driving the aviation industry toward sustainable development.

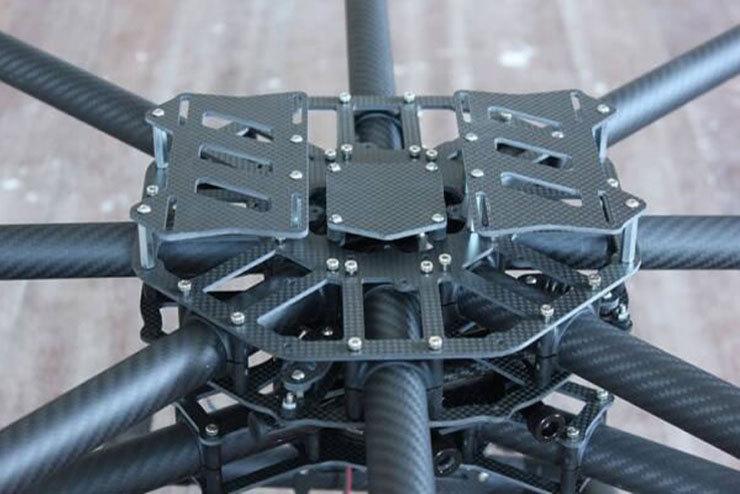

4. Lightweight Structures in Drones and Electric Aircraft

1. High-Altitude, Long-Endurance Drones

- High-altitude drones, such as the Global Hawk and Wing Loong series, require ultra-lightweight materials for long-endurance missions at extreme altitudes. Carbon fiber composites are used extensively in the drone's fuselage, wings, and propeller blades, enhancing flight time and payload capacity.

- In both military and civilian applications, the lightweight design of drones not only extends their endurance but also improves maneuverability and stealth capabilities.

2. Urban Air Mobility (UAM)

- With the rise of urban air mobility, electric vertical take-off and landing (eVTOL) aircraft are rapidly developing. Carbon fiber composites are widely used in the airframe and rotors to reduce weight and improve flight efficiency. For instance, Joby Aviation's eVTOL aircraft utilizes carbon fiber structures to ensure safe and efficient urban flights.

5. Rocket and Missile Casings

1. Rocket Structures: SpaceX Falcon 9

- SpaceX’s Falcon 9 rocket incorporates carbon fiber composites in its fuel tanks and rocket sections to increase the thrust-to-weight ratio and payload capacity. This not only improves rocket efficiency but also reduces launch costs, making space missions more economically viable.

2. Missile Systems

- In modern missile systems, carbon fiber composites are frequently used for missile casings to ensure structural integrity during high-speed flight and intense vibrations. The high strength and impact resistance of this material improve targeting precision and range.

6. Advantages of Carbon Fiber Composites Compared to Traditional Materials

| Property | Carbon Fiber Composites | Aluminum Alloys | Titanium Alloys | Steel |

|---|---|---|---|---|

| Density (g/cm³) | 1.6 | 2.7 | 4.5 | 7.8 |

| Strength (MPa) | 3500 | 550 | 900 | 500 |

| Stiffness (GPa) | 230 | 70 | 110 | 210 |

| Thermal Expansion Coefficient (×10⁻⁶/°C) | 0~2 | 23 | 8.6 | 11 |

| Corrosion Resistance | Excellent | Moderate | Good | Moderate |

- High Strength-to-Weight Ratio: Carbon fiber composites have a significantly higher strength-to-weight ratio than aluminum and titanium alloys, making them ideal for weight reduction and efficiency improvements in aerospace applications.

- Exceptional Thermal Stability: Compared to metals, carbon fiber composites exhibit minimal dimensional changes under extreme temperatures, which is critical for precision in spacecraft structures.

- Long Lifespan and Corrosion Resistance: Exposed to harsh environments at high altitudes and in space, aerospace equipment needs to withstand severe corrosion challenges. Carbon fiber composites excel in corrosion resistance, extending the lifespan of the equipment.

7. Conclusion

The application of carbon fiber composites in the aerospace sector is becoming an inevitable trend. Its lightweight, high-strength, and exceptional environmental adaptability not only enhance the performance and efficiency of aircraft but also pave the way for sustainable advancements in aerospace technology. As aerospace missions continue to evolve and technology advances, the potential of carbon fiber composites will be further explored, driving innovations that will shape the future of flight.