APPLITION FIELD OF CARBON FIBER COMPOSITE MATERIALS

HOME

ꄲ

APPLITION FIELD OF CARBON FIBER COMPOSITE MATERIALS

Carbon fiber reinforced polymer (CFRP) is widely used in various fields due to its unique properties. Below is a detailed introduction to some of the main application areas.

1. Aerospace

Carbon fiber composite materials play a crucial role in the aerospace industry. Their lightweight, high strength, and high-temperature resistance make them ideal for manufacturing structural components of spacecraft and aircraft. For example, approximately 50% of the materials used in large commercial aircraft such as the Boeing 787 and Airbus A380 are made from CFRP, which not only reduces the weight of the aircraft but also improves fuel efficiency and passenger comfort. Additionally, CFRP is essential in missiles, satellites, and launch vehicles, significantly enhancing their performance and reliability.

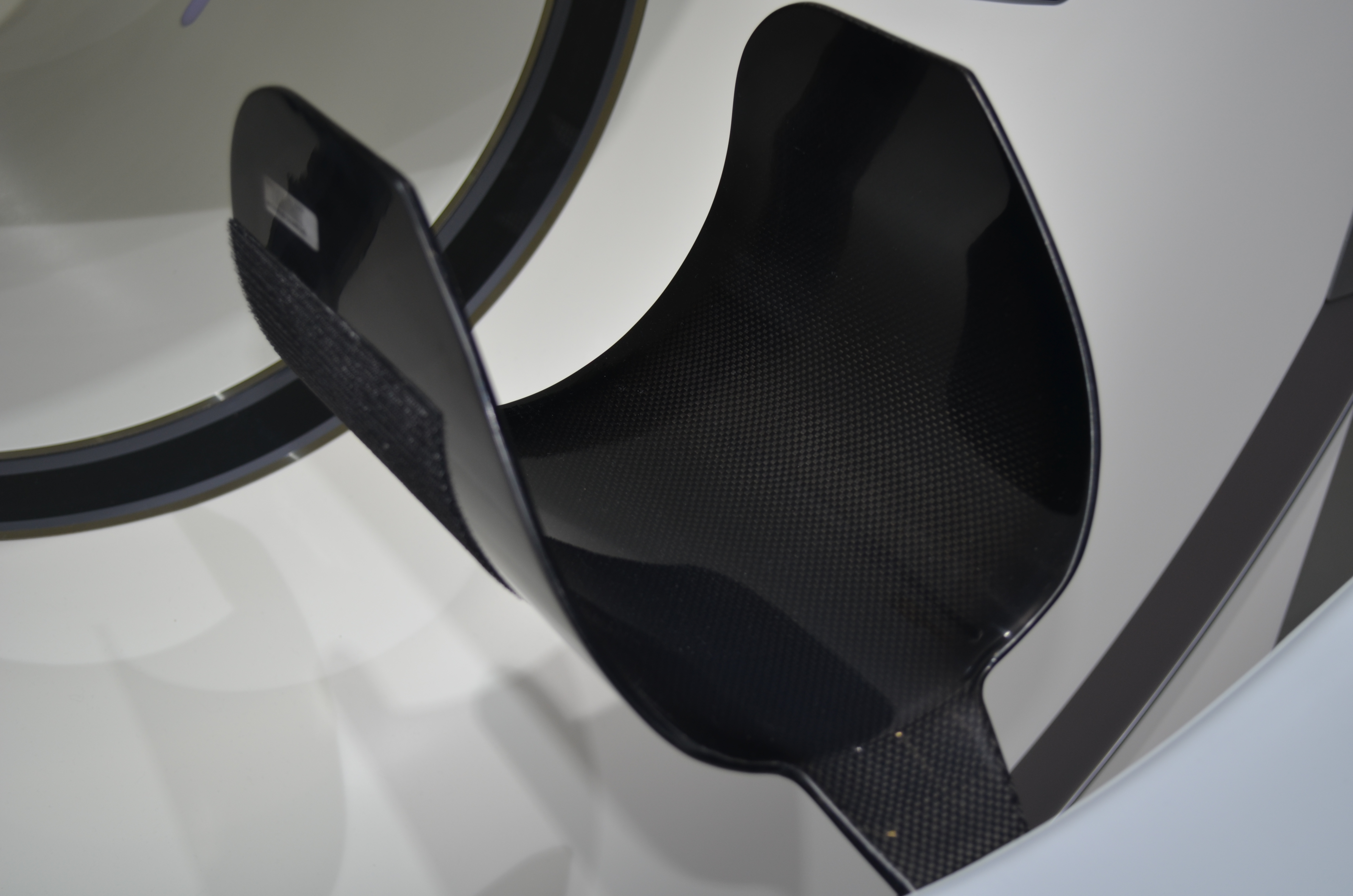

2. Automotive Manufacturing

In the automotive industry, carbon fiber composite materials are considered vital for achieving lightweight designs. Many high-end automobile manufacturers have begun using CFRP to reduce vehicle weight and improve fuel economy. For instance, components like carbon fiber hoods, seats, and mirrors can decrease the overall weight of a vehicle by 30% to 60%, thereby enhancing energy efficiency and safety. Moreover, the impact resistance of CFRP surpasses that of traditional metal materials, increasing vehicle safety during collisions.

3. Medical Devices

Carbon fiber composite materials also show great potential in the medical field. Due to their lightweight and chemical stability, CFRP is used to manufacture medical bed frames, surgical instruments, and imaging devices. For example, carbon fiber medical bed frames have an X-ray transparency rate as high as 97%, providing clearer imaging results while being about 45% lighter than traditional materials. Additionally, CFRP exhibits excellent corrosion resistance against common medical substances like drugs and blood, making it more durable in medical environments

4. Rail Transportation

With the development of high-speed railways, carbon fiber composite materials are gradually becoming essential in the rail transportation sector. CFRP can effectively reduce train body weight while improving high-speed performance, lowering energy consumption, and reducing environmental pollution. In next-generation high-speed trains, using carbon fiber composite materials can decrease the overall weight by 30%, saving energy and enhancing operational efficiency. This trend is becoming an important direction for future rail transportation development.

5. Sports Equipment

In the sports industry, carbon fiber composite materials are widely used in various sporting goods due to their excellent strength and toughness. Products such as badminton rackets, tennis rackets, fishing rods, and bicycle frames are made from CFRP to enhance performance and durability. These products not only improve athletes' competitive performance but also meet consumers' demands for high-performance sports equipment.

6. Construction and Civil Engineering

The application of carbon fiber composite materials in construction and civil engineering is increasing. They are used to reinforce existing structures like bridges and tunnels to enhance their load-bearing capacity and durability. CFRP's excellent corrosion resistance and flexibility can effectively extend the lifespan of buildings. Furthermore, due to its lightweight characteristics, using CFRP in new large structures can significantly reduce construction costs and time.

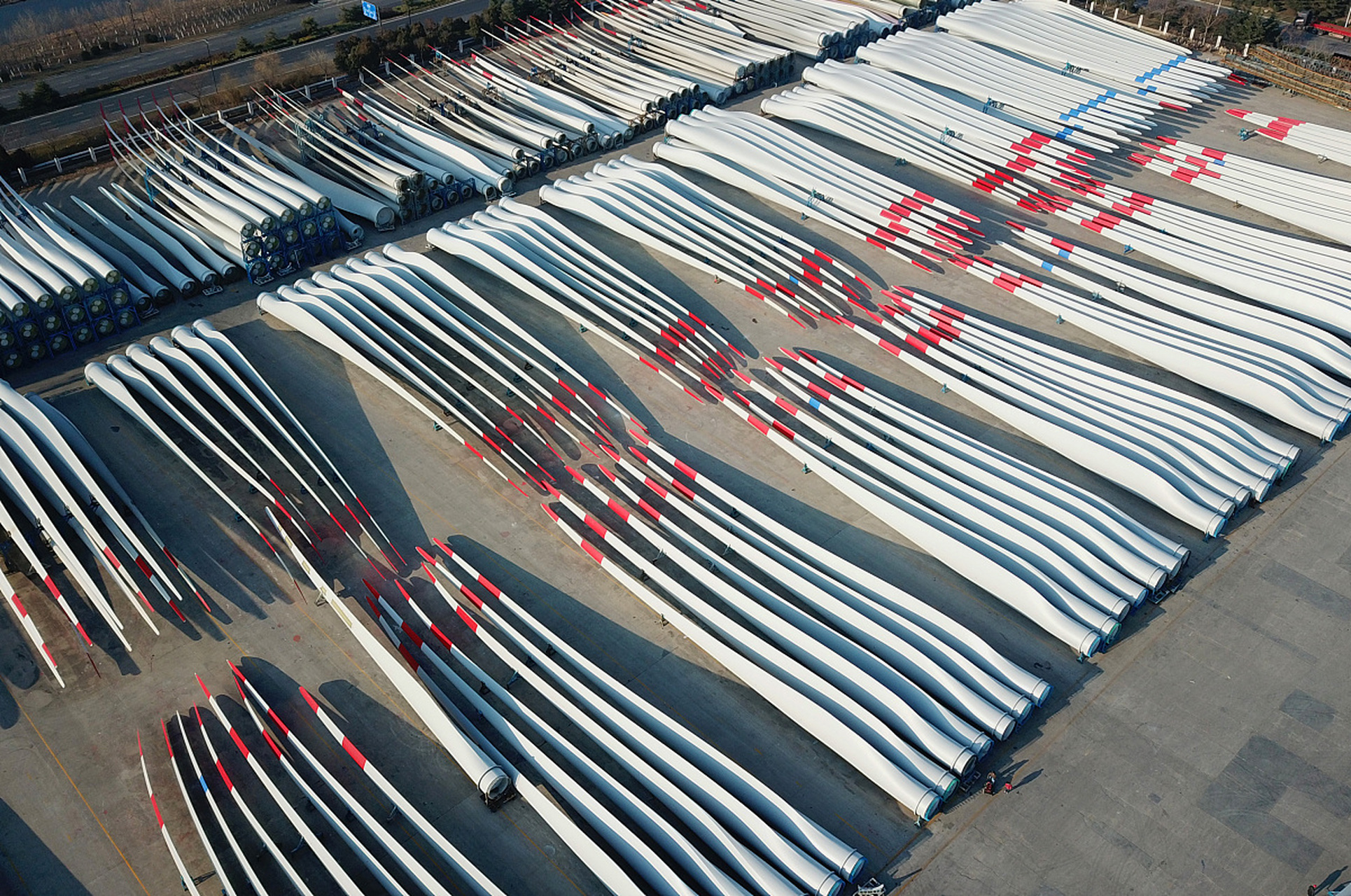

7. Wind Energy and Renewable Energy

With the growth of renewable energy sources, carbon fiber composite materials are increasingly used in wind turbine blades. CFRP provides the required strength and stiffness while reducing blade weight, thus improving power generation efficiency. When wind turbines exceed a power output of 3 MW, traditional glass fibers may no longer meet requirements; therefore, adopting carbon fiber composite materials becomes essential.

8. Defense and Military

In the defense sector, carbon fiber composite materials are used to manufacture military aircraft, drones, missiles, and other weaponry. These materials not only reduce equipment weight but also enhance maneuverability while offering good corrosion resistance that allows equipment to operate efficiently in harsh environments.