WHAT IS CARBON FIBER

1. Introduction of carbon fiber

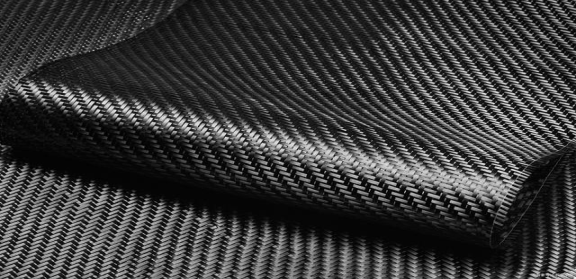

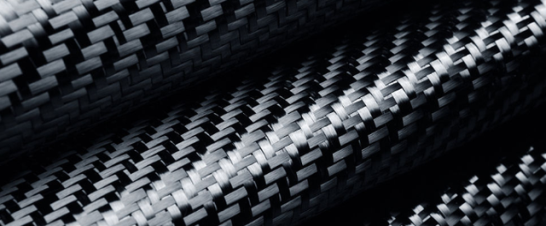

Carbon Fiber (CF) is a novel high-strength, high-modulus fiber material with a carbon content exceeding 95%. It is formed by stacking sheet-like graphite microcrystals and other organic fibers along the fiber axis, followed by carbonization and graphitization treatments to create a microcrystalline graphite material. Carbon fiber appears as black filaments, exhibiting good flexibility and can be processed into various fabrics. Its strength and modulus along the fiber axis are exceptionally high; for example, T800-grade carbon fiber has a tensile strength of up to 5400 MPa and a tensile modulus of nearly 300 GPa, with a density of only 1.7 g/cm³, earning it the titles of "King of New Materials" or "Black Gold." The diameter of carbon fiber is just 5 microns, equivalent to one-tenth to one-twelfth of a human hair, yet its strength surpasses that of aluminum alloy by four times.

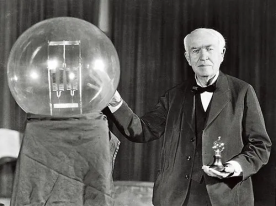

1.The origin of carbon fiber:The study of carbon fiber can be traced back to the 1870s. In 1860, British scientist Joseph Swan first used carbon filaments to manufacture light bulb filaments, marking the beginning of carbon fiber research. However, due to the limitations of vacuum technology at that time, research did not progress significantly. In 1879, inventor Thomas Edison also attempted to carbonize natural plant fibers such as cotton, hemp, and bamboo to obtain carbon fiber for use in incandescent bulb filaments. Unfortunately, inherent defects in these materials and the emergence of tungsten filament technology led to a temporary stagnation in carbon fiber research.

|

|

| (Joseph Swan) | (Thomas Edison) |

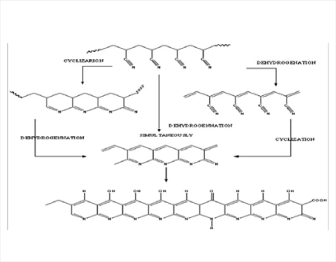

2.The birth of carbon fiber:In the 1950s, the United States reinitiated carbon fiber research to address issues related to high-temperature resistance and corrosion in missile technology, leading to the development of acrylic fiber technology. In 1959, Japanese scientist Akio Kondo invented polyacrylonitrile (PAN)-based carbon fiber. Due to its mature production processes, excellent overall performance, and lower production costs, this type of carbon fiber quickly became the market leader. Today, PAN-based carbon fiber is widely applied across various fields, driving industry advancement.

|

|

2.Application of carbon fiber

Carbon fiber possesses the unique characteristic of being "soft on the outside, strong on the inside." It is lighter than aluminum metal but stronger than steel, with corrosion resistance and high modulus properties, making it an important material in both defense and civilian sectors. Carbon fiber not only combines the inherent properties of carbon materials with the flexibility of textile fibers but also serves as a reinforcement material when combined with resins, metals, ceramics, and carbon, resulting in advanced composite materials. For instance, carbon fiber reinforced epoxy resin composites have the highest specific strength and modulus among existing engineering materials. Carbon fiber is a crucial strategic material for national defense and economic development, initially applied in military weaponry and aerospace. Furthermore, carbon fiber has penetrated various aspects of daily life, including wind turbine blades, sports leisure, automotive applications, pressure vessels, structural reinforcement, carbon-carbon composites, electronics, marine applications, cable cores, and rail transportation. The quantity of carbon fiber used has become an important indicator of a country’s economic and military development levels, significantly impacting national defense security and benefiting various facets of daily life.